Transporting drywall efficiently requires careful planning‚ proper tools‚ and adherence to safety guidelines to prevent damage during loading‚ unloading‚ and transportation processes․

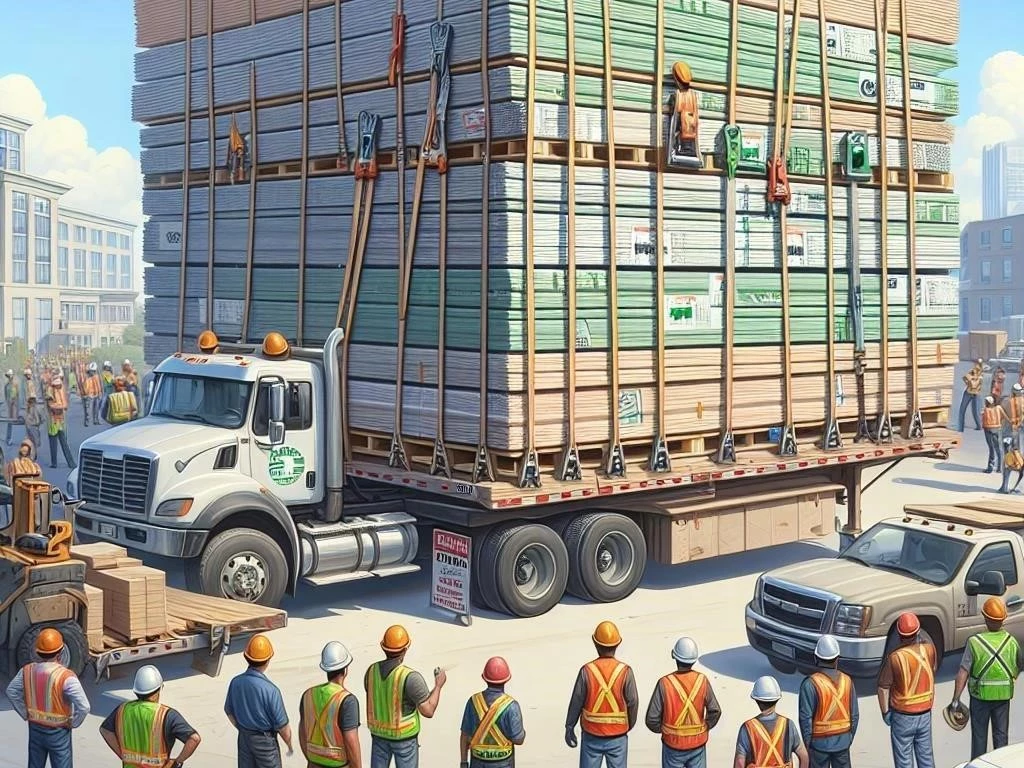

Understanding the Importance of Proper Transportation

Proper transportation of drywall enhances construction efficiency‚ minimizes damage risks‚ and ensures safety throughout the delivery process‚ benefiting both workers and project timelines significantly․

1․1 Safety Considerations in Drywall Transportation

When transporting drywall‚ safety must be a top priority․ Ensure that all panels are secured properly within the vehicle to prevent shifting during transit․ Utilize appropriate tools such as straps and padding‚ which aid in securing the cargo while also protecting the panels from damage․ Weight distribution is crucial; make sure to evenly distribute the weight throughout the cargo space to maintain vehicle stability․ Always follow best practices for handling drywall‚ which include wearing protective gear to prevent injury during loading and unloading․ Familiarize yourself with the vehicle’s guidelines for maximum weight limits to avoid strain․ Proper planning and logistics are essential for safe maneuvering‚ ensuring a secure and efficient delivery process while minimizing risks of accidents or damage․

1․2 Impact on Construction Efficiency

The efficiency of transporting drywall directly influences overall construction timelines and project costs․ Timely delivery of drywall panels allows for smoother scheduling of installation tasks‚ preventing delays that could hinder other construction activities․ Proper handling‚ loading‚ and unloading techniques significantly reduce the risk of damage‚ ensuring that materials arrive in good condition‚ which minimizes wastage and additional expenses․ Effective logistics planning enhances the use of available cargo space‚ allowing for the transport of more materials in fewer trips․ This not only saves time but also optimizes fuel usage and reduces transportation costs․ Overall‚ a well-executed transportation process streamlines operations on-site‚ ensuring that construction projects remain on track and within budget‚ ultimately boosting productivity and enhancing project outcomes․

Preparing for the Delivery

Preparing for drywall delivery involves selecting the appropriate vehicle‚ planning logistics‚ and ensuring all necessary tools and equipment are ready for efficient transportation and unloading․

2․1 Choosing the Right Vehicle for Transporting Drywall

Selecting the appropriate vehicle for transporting drywall is crucial for ensuring safe and efficient delivery․ A truck with a spacious cargo area specifically designed for carrying construction materials is ideal․ Consider a flatbed or box truck that can accommodate standard drywall panel sizes and quantities․ Additionally‚ the vehicle should possess adequate weight capacity to handle the load without exceeding safety guidelines․ Assessing the interior dimensions is essential to ensure proper fit and secure loading․ Ensure the vehicle is equipped with necessary features‚ such as tie-down points‚ for securing the panels effectively․ Furthermore‚ inspect the vehicle for any existing damage that could compromise safety during transportation․ Choosing the right vehicle enhances logistics efficiency and minimizes risks associated with delivering drywall․

2․2 Planning the Logistics of the Delivery

Effective logistics planning is essential for the successful transportation of drywall․ Begin by determining the delivery schedule‚ taking into account construction timelines and any potential obstacles‚ such as traffic or weather conditions․ Identify the best route to optimize travel efficiency and minimize delays․ Coordinate with the receiving site to ensure that unloading areas are accessible and prepared for the arrival of the truck․ Additionally‚ communicate with the loading team to establish clear timelines and expectations for loading drywall into the vehicle․ Ensure that all necessary tools and equipment are available for loading and unloading‚ which can enhance safety and efficiency․ By carefully planning logistics‚ you can streamline the delivery process and contribute to a successful construction project․

Loading Drywall Panels into the Truck

Loading drywall panels properly into the truck is vital for preventing damage‚ ensuring safety‚ and optimizing space‚ thereby facilitating a smooth transportation process for delivery․

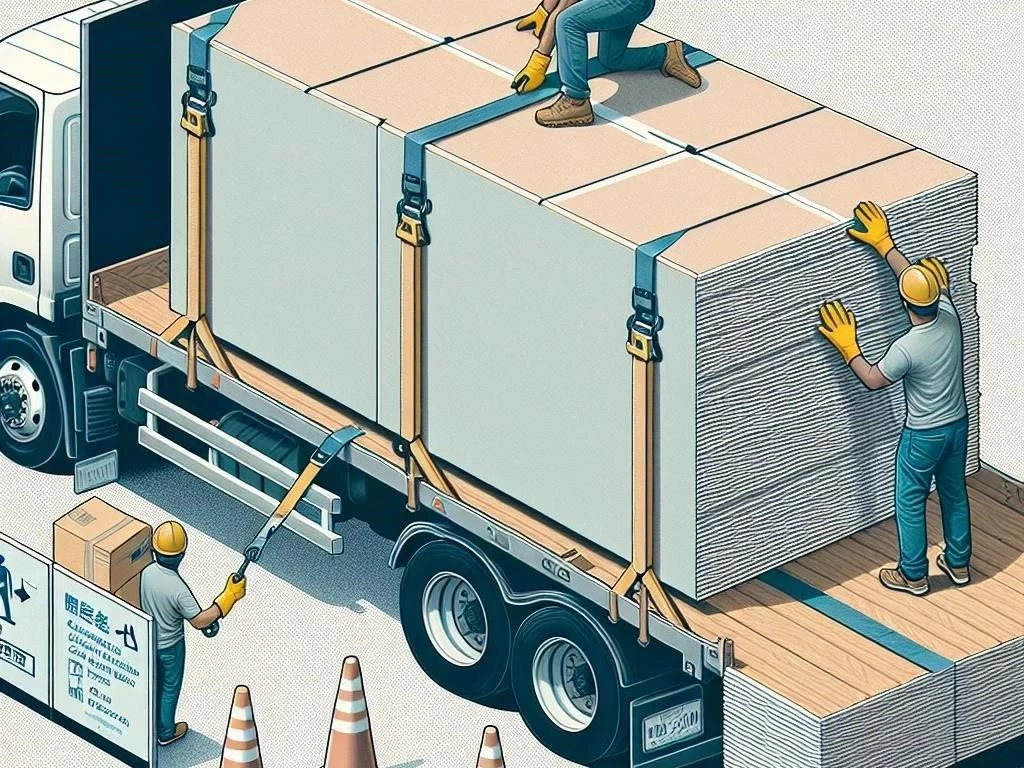

3․1 Best Practices for Handling Drywall

Handling drywall requires careful techniques to ensure safety and prevent damage․ Always wear appropriate protective gear‚ including gloves and safety glasses‚ to avoid injuries․ When lifting panels‚ use proper body mechanics: bend at the knees and keep your back straight to reduce strain․ Utilize a team approach for larger panels‚ as this facilitates safer lifting and maneuvering․ Handle panels vertically whenever possible; this reduces the risk of bending or breaking․ Use padding or blankets to protect edges and surfaces during transport․ Ensure that the loading area is clear and free from hazards to prevent accidents․ Finally‚ communicate effectively with your team throughout the loading process to coordinate movements and ensure that everyone is aligned on handling techniques․

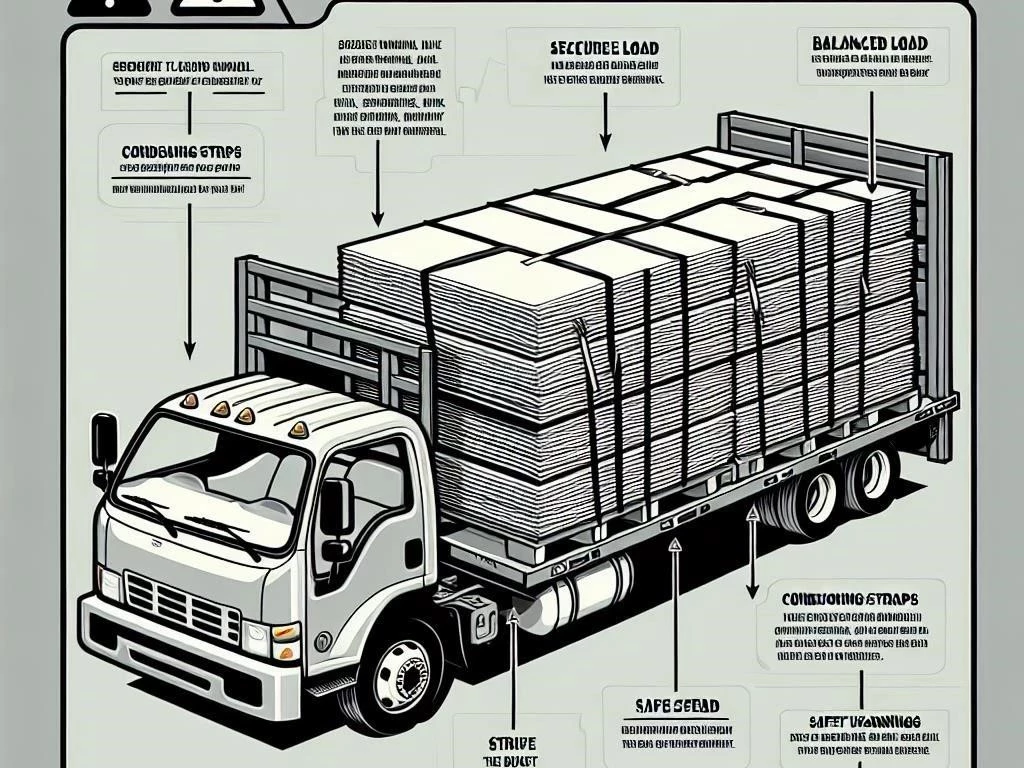

3․2 Weight Distribution and Cargo Space Optimization

Proper weight distribution and cargo space optimization are critical when loading drywall into a truck․ Start by placing heavier panels at the bottom and towards the center to maintain vehicle stability during transit․ Ensure that the weight is evenly distributed across the truck’s cargo space to prevent any tipping or swaying while driving․ Utilize vertical stacking to maximize cargo space‚ but be cautious not to exceed the vehicle’s height limits․ Secure the panels with straps or ropes to prevent movement during transport‚ which can lead to damage․ Assess the layout and positioning of each panel to ensure that space is used efficiently‚ allowing for more materials to be transported in fewer trips‚ ultimately enhancing delivery efficiency and reducing costs․

Securing Drywall During Transportation

Securing drywall during transportation is essential for preventing damage‚ ensuring safety‚ and maintaining stability while on the road‚ thereby facilitating a smooth delivery process overall․

4․1 Tools and Equipment for Securing Panels

To secure drywall panels effectively during transportation‚ several tools and equipment are essential․ First‚ use high-quality straps designed for heavy loads; these can be ratchet straps or cam buckle straps that provide strong tension․ Additionally‚ corner protectors can prevent damage to panel edges by distributing pressure evenly․ Employ padding materials such as blankets or foam to cushion the panels‚ reducing the risk of scratches or dents․ A hand truck or dolly can assist in moving and positioning drywall within the truck․ Also‚ consider using tie-downs or cargo nets to ensure that panels remain in place throughout transit․ Lastly‚ having a level or measuring tape can help verify that the load is balanced and secure‚ thus enhancing transportation safety․

4․2 Using Straps and Padding for Damage Prevention

Employing straps and padding is crucial for preventing damage during drywall transportation․ Straps should be tightly secured around the panels to keep them in place and prevent shifting‚ which can lead to cracks or breaks․ Utilize ratchet straps for added tension‚ ensuring that they are not overly tight to avoid panel deformation․ Padding‚ such as foam or moving blankets‚ should be placed between panels and against the truck’s interior to absorb shock and prevent scratches․ Corner guards can further protect edges from damage during transit․ Additionally‚ ensure that straps do not rub against the drywall surface‚ as this can cause wear and tear․ By combining straps and padding‚ you create a protective environment that minimizes the risk of damage throughout the delivery process․

Unloading Drywall Safely

Unloading drywall safely requires careful techniques‚ teamwork‚ and proper tools to prevent injury and damage‚ ensuring an efficient process upon arrival at the construction site․

5․1 Maneuvering Techniques for Safe Unloading

Safe unloading of drywall panels requires effective maneuvering techniques to prevent injuries and damage․ Begin by assessing the unloading area to ensure it is clear and accessible․ Use a hand truck or dolly to transport multiple panels at once‚ which reduces the risk of dropping them․ When lifting panels manually‚ always bend at the knees and keep the load close to your body to maintain balance and stability․ Coordinate with your team to lift and move larger panels‚ ensuring everyone is aware of their roles․ Utilize proper communication to signal when to lift‚ lower‚ or move the panels․ Additionally‚ avoid twisting your body while carrying panels; instead‚ pivot your feet to change direction․ This reduces strain and enhances safety during the unloading process․

5․2 Guidelines for Handling Drywall Panels on Site

When handling drywall panels on-site‚ following proper guidelines is essential to ensure safety and prevent damage․ Always inspect each panel for any visible defects or damage before unloading․ Utilize protective gear‚ such as gloves and safety goggles‚ to safeguard against injuries․ When transporting panels‚ maintain a vertical position to minimize the risk of bending or breaking․ Use appropriate lifting techniques‚ ensuring that the load is balanced and that you have a clear path to your destination․ Communicate effectively with your team to coordinate movements‚ especially when navigating tight spaces․ Avoid leaning or placing undue weight on the panels‚ as this can lead to structural compromise․ By adhering to these guidelines‚ you can enhance safety and efficiency while working with drywall on-site․